09-11-2025

A recent publication in the International Journal of Production Research highlights Purdue University’s leadership in supply chain innovation. The study, led by researchers from the Mitch Daniels School of Business and the College of Engineering, introduces a new strategic supply chain resiliency index — a unified metric that evaluates resilience based on network structure, supplier reliability (especially geopolitical risk), and the contribution of each supplier.

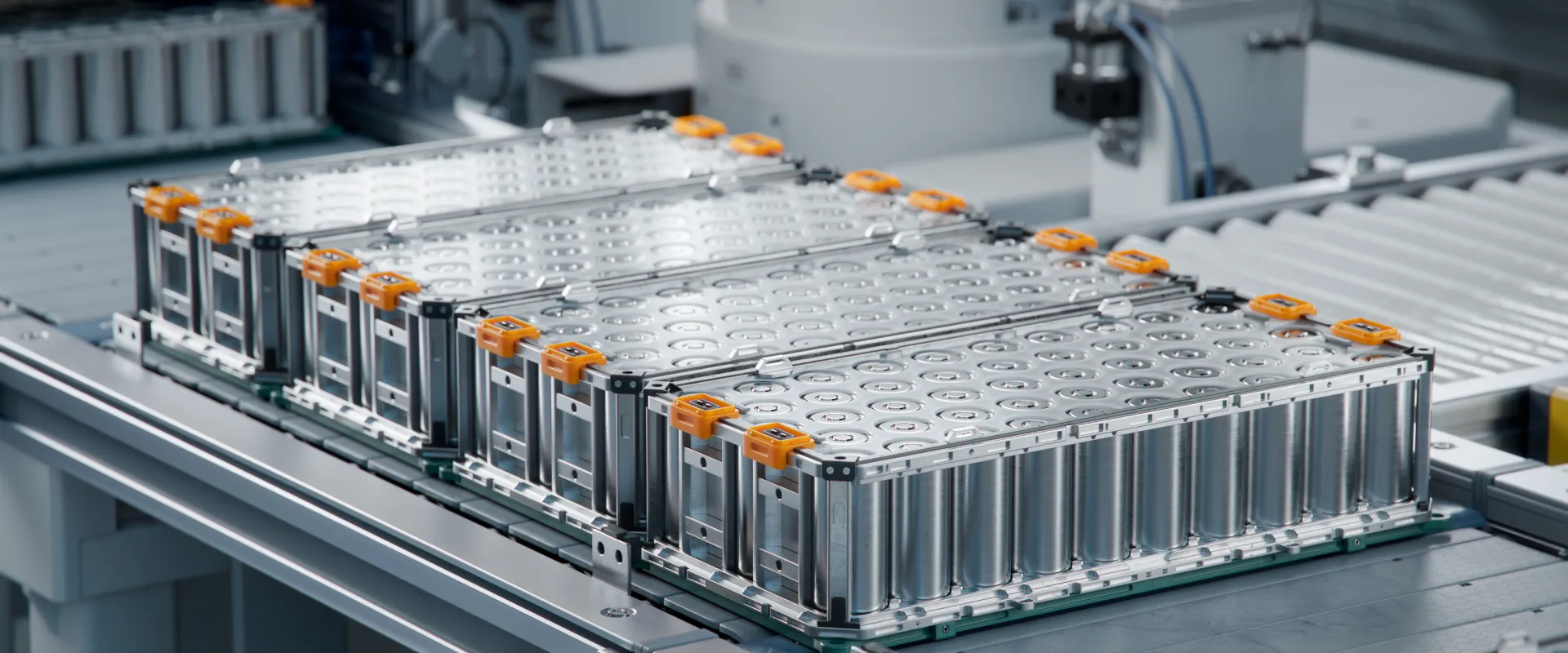

The supply chain resiliency index, or SRI, developed by the Dauch Center for the Management of Manufacturing Enterprises (DCMME) at the Daniels School of Business, enables supply chain leaders to benchmark existing networks, evaluate strategic decisions and assess the implications of new technologies. The study examines the lithium supply chain supporting U.S. electric vehicle production, revealing that automakers — such as General Motors and Tesla — are already strengthening their resilience through diversified sourcing strategies.

“This index helps leaders make smarter, data-driven decisions about their supply networks,” says Stephan Biller, DCMME director and the Harold T. Amrine Distinguished Professor in the Edwardson School of Industrial Engineering and Daniels School of Business. “It also reflects the power of cross-disciplinary collaboration, which is central to Purdue’s eXcellence in Manufacturing and Operations initiative.”

The research was publicly presented at DCMME’s spring conference and exemplifies the center’s mission of interdisciplinary impact. For more than 30 years, DCMME has brought together faculty from industrial engineering, electrical and computer engineering, civil engineering and Purdue Polytechnic to solve real-world problems in manufacturing and supply chain strategy.

Founded in the late 1980s with the support of automotive executive Dick Dauch, DCMME remains focused on achieving U.S. competitiveness. “DCMME is vital to keeping American manufacturing lean, flexible, smart, innovative and profitable,” Dauch said at the time. That legacy continues through research and education that prepares students and companies for today’s challenges.

Beyond research, the center engages with industry every semester through the Griswold Internship Program, experiential learning, and center projects involving 140 to 160 students in applied projects that deliver real-world results. The Faculty Fellows program further promotes cross-campus innovation by matching professors from different schools to tackle high-impact topics.

Published in July 2025, the International Journal of Production Research article appears in one of Taylor & Francis’s leading journals. As one of the first practical strategic frameworks for measuring supply chain resiliency, the SRI is a timely contribution to a field that is gaining global attention across business, academia and government.