02-26-2025

My unique Integrated Business and Engineering (IBE) major is a gem. It has given me the chance to learn both business and engineering. Both apply to my future career and internships. I feel grateful to go to a school that invests in my future.

One of the opportunities Purdue has given us is the IBE Inaugural Business, Design & Prototyping Challenge. This project was a combination of business, engineering and coding. The principle is to bring an engineering product to market with a Purdue theme. The first thing I needed was a team. — Ryan Harrison

Ryan, a brother in my fraternity, brought the Business, Design & Prototyping Challenge to my attention. He had assembled a group of business majors, engineering majors and data science majors from Phi Delta Theta. Needing someone knowledgeable in coding and 3D modeling, he asked me to join. As a mechanical engineering technology major, I had both. I decided to be part of the team because I’d gain hands-on learning, be a part of a group from diverse backgrounds and get to know those in Phi Delta Theta on an academic level.

We registered for the Business, Design & Prototyping Challenge and went to work on crafting ideas. Purdue gave us the funding to make our prototype for this competition. It was exciting having the freedom to choose every aspect of our project.

We were knocking around ideas late one night when an idea from my trips to Chicago came to us: a topographical bus map. — Nate Moyer

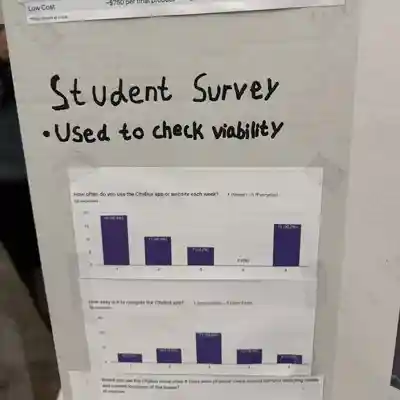

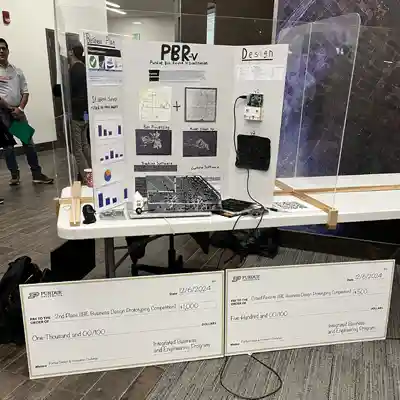

We decided on a Purdue Bus Route visualization (PBR-v) as our project. We wanted to build a 3D-printed map of campus that would display where every Purdue bus was at any given time. We wanted this map to be as accessible as possible. It was to be an accurate scale model that students could touch. The point was to make it visibly easy to identify where each bus was. LED lights would light up each bus at their destinations. This would help when students are going to leave class and can get a sense of how long they have for the next bus. During an Indiana winter, this would be especially helpful.

We were ambitious and wanted access to live data for our presentation, but our IBE team members had to reign us in. Ryan told us it wasn’t pragmatic to do this with our limited resources and budget. We had to be smarter about how we went about our project.

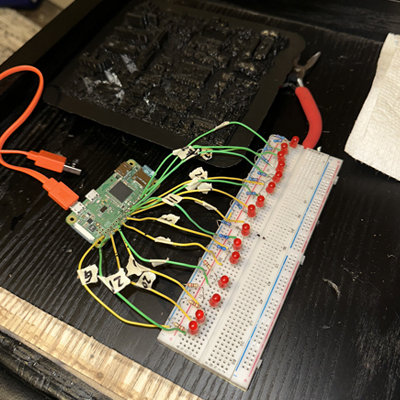

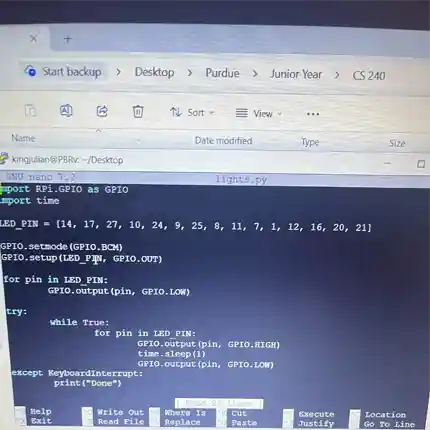

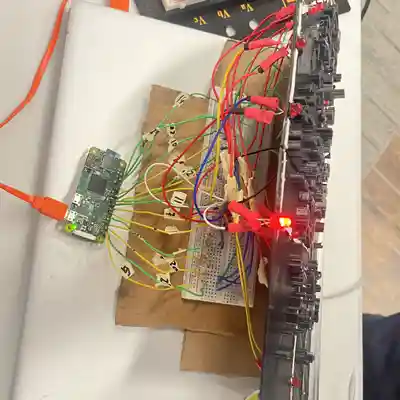

My part was to code our project using a Raspberry Pi, a small and affordable computer that's used for creating projects and automating tasks. It's versatile and when connected to the internet it can track online APIs. We were unable to connect to City Bus to use their data, but in theory, the computer in our model would track the live location of each bus.

We wrote code for the LEDs to light up on the 3D model when buses were en route. — Peter Hogan

Our first step in rendering our 3D model was to build a 2D model of campus. This model laid out buildings and gave us a better sense of what we could cut from our prototype. We then took that model and transformed it into a 3D image. The software we used had multiple errors that I had to individually go back and change. I did this over the semester while the other team members worked on coding, budgeting and our presentation.

Finally, after months of work, it was time to print. — Nate Moyer

One of the most important parts of a team is having a collective name. During one of our late-night study sessions, we were throwing names back and forth. None seemed to stick or connect to our project. Then an idea formed.

Our favorite movie, Madagascar, has a character named King Julian. His trademark line is “Move it. Move it.” At that moment it was decided. Our team name for a project marking the movement of campus buses would be named after the iconic King Julian. — Peter Hogan

Every group project has obstacles they need to navigate together. There were different levels of ambition. We had to communicate our differences when it came to certain aspects of our project. We always listened to the team member who had the most knowledge of what was being discussed. For 3D printing, I looked up to Nate and learned so much from him. I’m glad to know that after this project I can look to these guys in my professional life and personal life.

The week before the competition included many late nights, sometimes all-nighters. In our house, we were working constantly. Finalizing the 3D model, running the codes and adding finishing touches to our presentation. Our project was complicated, but we wanted our presentation to be digestible for our audience.

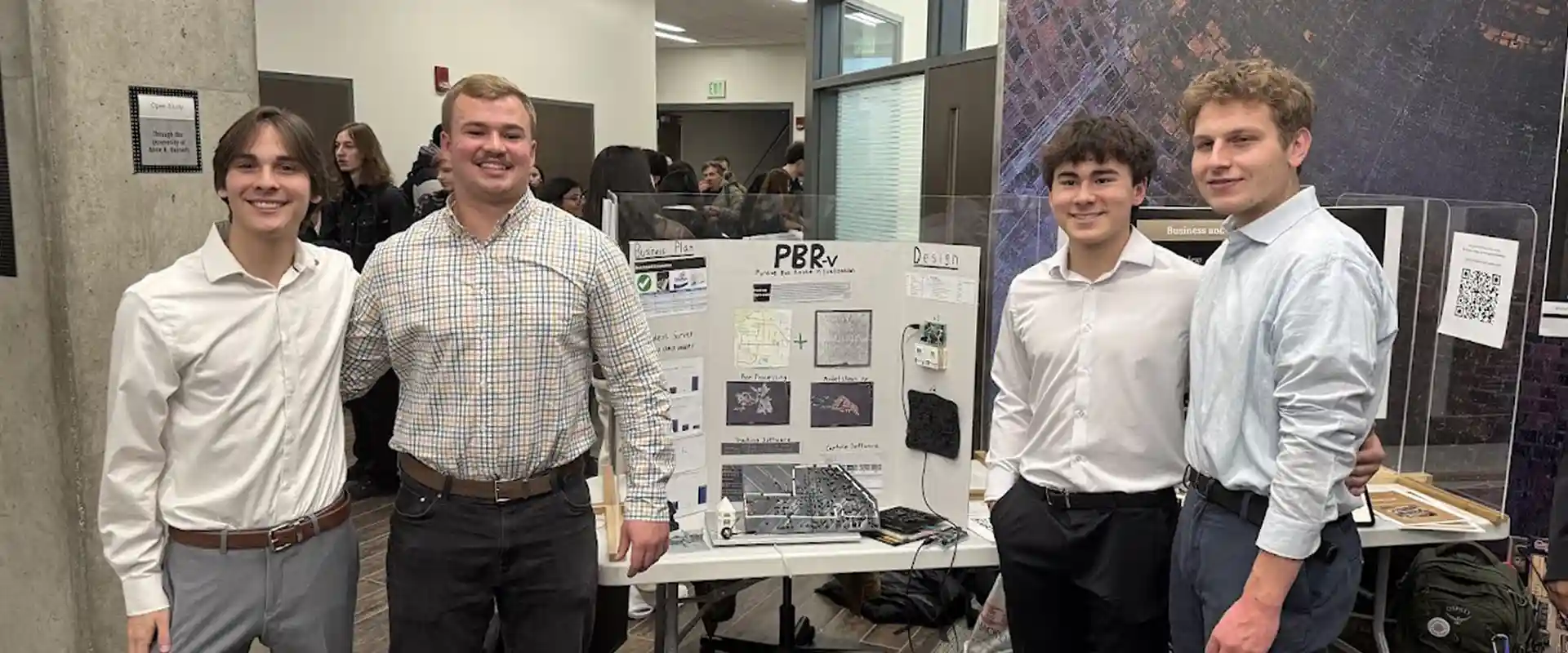

After countless hours put into our project, it was time for the competition. — Ryan Harrison

As one of the IBE team members, I looked forward to presentation day. Most of my school projects are either entirely business or engineering. I was excited to show how we combined engineering, coding and business. It was unlike any competition. We were ready to market a product that we tirelessly worked on.

The entire day we had students and adults alike telling us how they appreciated our project, how useful it was and how much they liked it. We were riding the tidal way of praise to the finishing line.

While the judges awarded us second place, we won crowd favorite, which was more important to us.

This was a testament to the time and work we put in. We were engaging with our audience, had a unique project, and people could tell we cared about what we were doing. It was fun working with my team, and I’m proud of what we created.

This competition accelerated our learning compared to sitting in a classroom. I recommend when these opportunities arise that you put yourself out there and learn something new. I became close to my teammates and learned skills I otherwise wouldn’t have had the opportunity to.

Lastly, in the wise words of our inspiring King Julian: “Move it. Move it.” — Lukas Jung

Ryan Harrison is from Los Altos, California, and attended Bellarmine College Preparatory. He is a sophomore studying industrial engineering and integrated business and engineering at the Mitch Daniels School of Business. He is a member of Phi Delta Theta fraternity. He is also a member of the Institute of Industrial and Systems Engineering.

Nate Moyer is from Chicago, Illinois, and is a junior studying mechanical engineering technology at the Polytechnic School at Purdue University. He has a minor in psychology and a certificate in entrepreneurship. He is a member of Phi Delta Theta Fraternity. He was a facilities engineer intern for Sullair last summer.

Peter Hogan is from Ballwin, Missouri, and is a junior studying Data Science at Purdue University. He is a member of Phi Delta Theta fraternity and was previously house manager and recruitment chair. This summer he is interning with Stryker in Portage, Michigan.

Lukas Jung is from San Francisco, California, and graduated from Pinewood School. He is an honors student at Purdue University studying integrated business and engineering at the Mitch Daniels School of Business with a minor in computer science. Last summer he worked as a project management intern for dormakaba Americas in Indianapolis, Indiana.